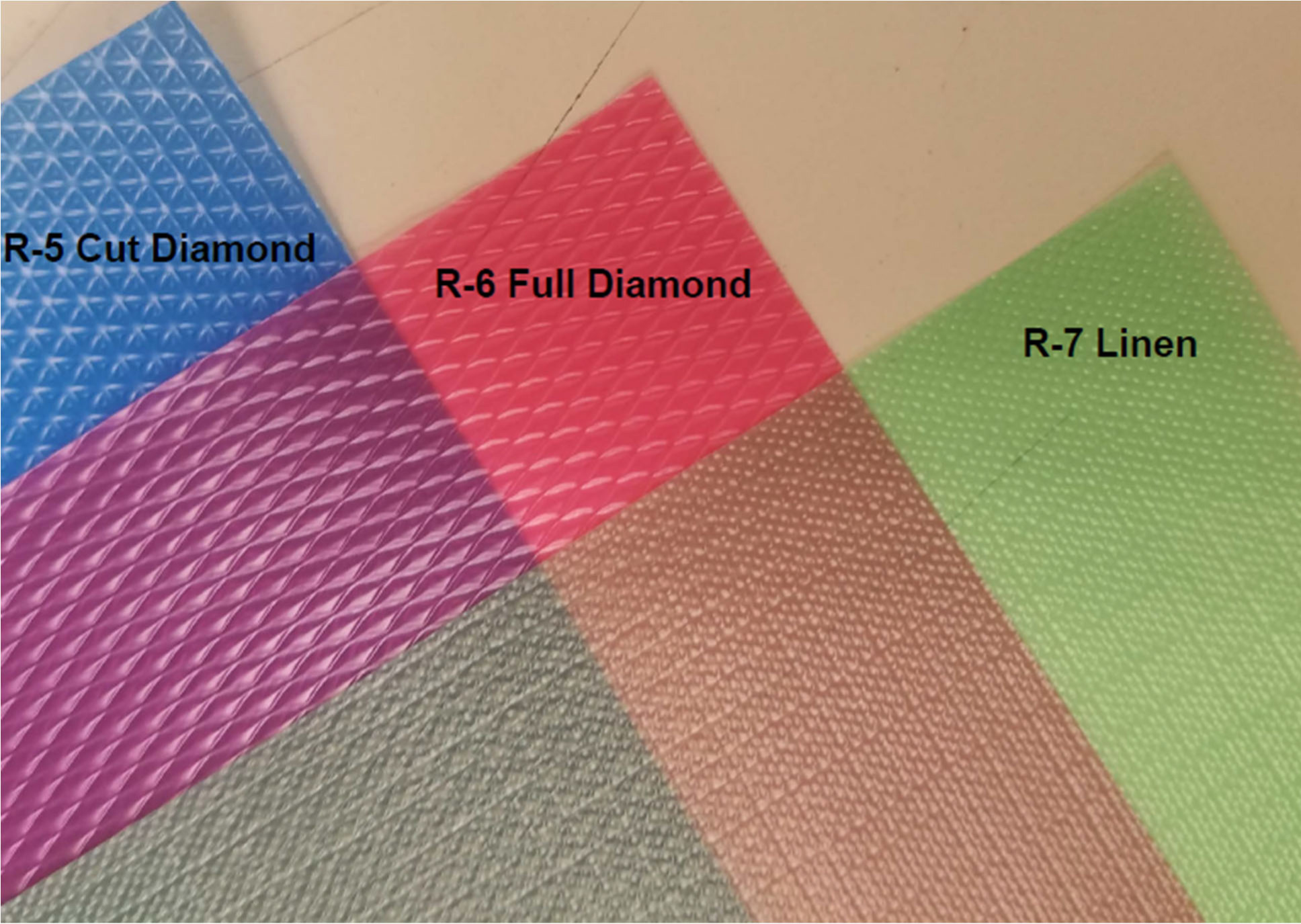

Mor Plastic Industries “R Series®” features an 88” embossed line to compliment our very successful R-Series smooth release film formulations. Our highly sophisticated production line allows us to deliver even mil thickness across the web – critical in areas where “down-gauging” is desirable. R5 Cut Diamond and R6 Full Diamond patterns of release films are ideal for narrow web, high-tack applications. Low-profile R7 Linen Embossed release film offers productivity advantages similar to smooth film, yet has a slight profile to allow maximum release.

Mor Plastic Industries “R Series®” features an 88” embossed line to compliment our very successful R-Series smooth release film formulations. Our highly sophisticated production line allows us to deliver even mil thickness across the web – critical in areas where “down-gauging” is desirable. R5 Cut Diamond and R6 Full Diamond patterns of release films are ideal for narrow web, high-tack applications. Low-profile R7 Linen Embossed release film offers productivity advantages similar to smooth film, yet has a slight profile to allow maximum release.

After twenty-five years of product development in the North American market, Mor Plastic Industries has refined its formulations to work in virtually every rubber calendaring and extrusion application including belts, hoses, tires, rollers, roofing, and custom calendar applications.

R5 Datasheet

R6 Datasheet

R7 Datasheet

| Brand Name | Industry Applications |

| R5,R6,R7 | Cold Calendaring Process (up to 40°) |

| Inner Liners | |

| Sidewalls | |

| Cheffers | |

| Gum Strips Applications | |

| Cord Calendar | |

| Other Sticky Materials |

Benefits:

- Maintain clean and fresh rubber compound surface

- Prevent contamination

- 100% recyclable

- Significant savings in storage space

- Eliminates the extra machinery of rewinding and repairs of cloth liners

- Saving on initial capital investment required for cloth liners

- Excellent product quality. No wrinkles, keeping the material fresh and tacky with a clean surface and without contamination

- Saves cost by reducing the quantity of tacky resin

- Tailor made to desired width, length, thickness and color

- Easy and clean release and peel

- High mechanical properties

- Can be tailor-formulated for other special applications